3D System Strikes Partnership Deal With Konica’s Australian Arm

3D Systems, a leading manufacturer of 3D printers, has announced a partnership deal with Konica Minolta Business Solutions Australia, a Japan-based technology company. The partnership allows the former to gain access to Konica Minolta’s network of resellers and additive manufacturing solutions to expand its product portfolio.

Konica Minolta Australia’s move shows that the company is ready to dive into the 3D printing market. The dealership will focus on the manufacturing, architect market, print bureaus and education sectors.

“Our goal is to arm our nationwide, exceptional sales organisation with cutting-edge products, solutions and services that help our customers grow their business and gain a competitive edge,” said George Fryer, General Manager of Production Sales at Konica Minolta Australia, in a report by TCT Magazine.

The said partnership between 3DS and Konica Minolta is not the only indication of the current 3D printing boom in Australia. Local manufacturer 3D Stuffmaker recently unveiled its latest printer called CORE G2, a light industrial grade printer that has the capacity to print in large volumes using different materials. The 3D printer features a metal construction with 50 micron layer resolution, LCD control panels and high-resolution dual head printing capabilities that works in a soundless operation.

Available for US$1,995 [$2,468], the CORE G2 is one of the most affordable items in the company’s line of products. Steve Weatherly, director of 3D Stuffmaker USA, reveals that the CORE G2 aims to retract critical feedback with its high precision movements and accuracy.

“We always strive to achieve this outcome at a value price point that you can expect from 3D Stuffmaker. This machine will continue to raise the bar in the 3D printing space,” said Weatherly, as quoted by 3DPrint.com.

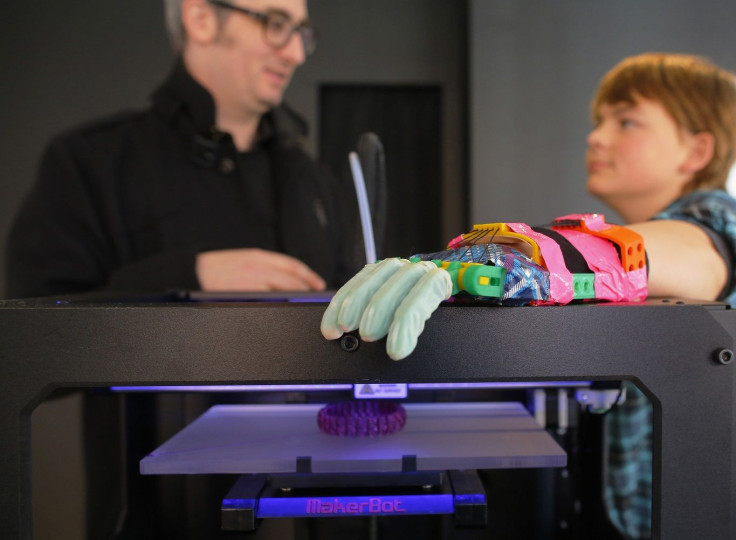

3D printing is becoming common in many industries, including in aerospace, in space exploration and in medical applications. Though these industries might be different from one another, they are similar in using titanium to carry out 3D printing or additive manufacturing processes.

Through 3D printing, titanium is used to build rocket ship engines and airplane parts, and used in creating body parts for surgeries and operations. This surge of the 3D printing technology and its applications for many sectors suggest a rising demand for titanium. The supply will surely meet this demand with the help of mining companies focusing on the metal. For example, White Mountain Titanium Corporation (OCTQB: WMTM), a titanium miner in Santiago, Chile, is aiming to produce 112 million tonnes of high-grade rutile, with an annual output of 480,000 tons. This kind of supply will ensure the longevity and establishment of the 3D printing business in Australia, and the rest of the world.

Contact the writer: a.lu@ibtimes.com.au