New Age Of Health And Recovery: Patients Receive Titanium Body Parts

The human body is a vessel, and just like any other powerful machine, it may deteriorate over time due to uncontrollable circumstances. Some are burdened with having to deal with damaged body parts, and most of the time, transplants and surgeries are the only hope for these patients.

In the United States alone, more than 120,000 people are on the waiting list for organ and body parts transplants, and the long wait is causing more stagnant lives than relief. But a new hope comes in the form of technological advancement, and that is titanium 3D printing. Stem cell therapies and 3D printing are currently trending in the medical industry as they offer new ways to treat a wide variety of immobilising conditions.

There are already several cases of patients receiving various body parts made from titanium 3D printing, and here are some of them:

In South China’s Shenzhen Hospital, a 27-year-old woman went through a high-risk surgery to replace her scapula (shoulder blade) with a titanium replacement. It is said that the patient’s shoulder blade was thoroughly damaged by a tumour. In a year, the woman’s shoulder had deteriorated significantly after noticing pains and cramps.

Based on several CT scans and an MRI, doctors conclude that the woman suffered from an invasive tumour in her scapula. The Oncology department later revealed that the tumour will conquer good bones and most of the woman’s shoulder ones have already been “eaten” away. To give the woman a chance for a successful rehabilitation, doctors turned to creating a 3D replica of her shoulder bone, using the patient’s medical data to make a plastic 3D printed prototype. The model was then sent to an artificial limb factory where the titanium replacement was created.

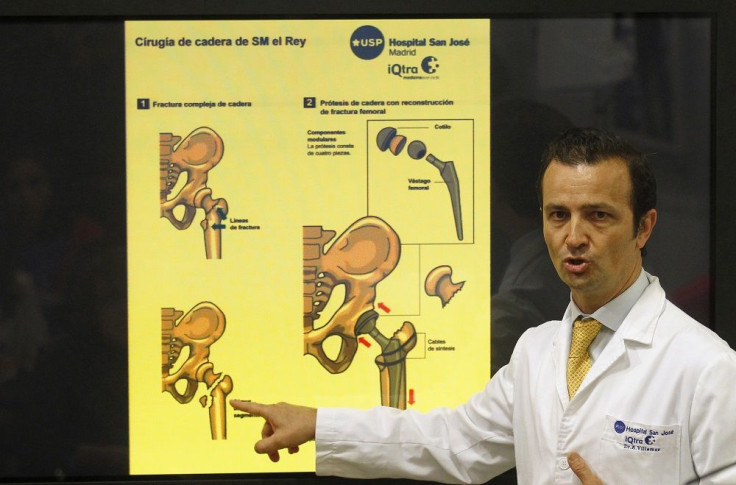

In the United Kingdom, a patient named Meryl Richards was given a second chance to live an active life with a 3D printed titanium hip replacement. Doctors at the University of Southampton combined stem cell therapy and 3D printing to replace Richard’s damaged hip, based on Richards’ CT scans’ results. The physicians used the patient’s own bone marrow to seed a graft behind the implant for a more natural healing.

Made from bone scaffold, the graft will allow blood flow as it attaches and supports the titanium implant. “The way medicine has evolved is fantastic. I hope that this will be the last time that I have to have a hip operation. I feel excited to have this pioneering surgery and I can see what a benefit it will have to me,” said Richards in a post by Med Gadget.

Now that titanium 3D printing is starting to get big in medicine, it only means that there will be a surge in the global demand for titanium. In Chile, a developing mining project is focusing on the production of high-grade titanium. White Mountain Corporation (OTCQB:WMTM) is on its way to produce 112 million tonnes of rutile, with a projected number of 80,000 tonnes per year. On the company’s fourth year of production, it is expected to yield over 130,000 tonnes of titanium. This development will prove to be beneficial to many patients around the world once titanium 3D titanium printing of body parts becomes a norm in hospitals.

To contact the writer, email: v.hernandez@ibtimes.com.au