NASA Challenges Designers To Build Habitat For Deep Space Exploration

NASA has taken 3D printing a step further by opening a competition that urges designers to build a habitat for deep space exploration using the additive process. NASA is partnering with the National Additive Manufacturing Innovation Institute, or widely known as America Makes, to offer $2.25 million in prizes for a design competition that wishes to build a 3D printed living sanctuary meant for deep space exploration, including NASA’s Mars journey.

As human beings, shelter is one of the most basic needs. In a world where humans are used to consuming much space and heavy materials to construct their homes, developing a way to do this with as minimum load and space possible for a distant planet is precious.

The competition is part of NASA’s Centennial Challenges programme. It aims to push the additive construction technology that will be used in building sustainable housing projects in for Earth and outside the planet.

The first phase of the competition will run through Sept 27, with details announced over the weekend in San Mateo, California. The first phase is described as a design competition that serves as a briefing for participants to design and develop advanced architectural concepts that will incorporate 3D printing. The top 30 submissions will be judged accordingly, and a cash prize of $50,000 will be given at the 2015 World Maker Faire to be held in New York.

Sam Ortega, NASA’s Centennial Challenges programme manager, seems optimistic about the designs that will be presented to the panel. “The future possibilities for 3D printing are inspiring, and the technology is extremely important to deep space exploration. This challenge definitely raises the bar from what we are currently capable of, and we are excited to see what the maker community does with it,” said Ortega in a post published by NASA’s official Web site.

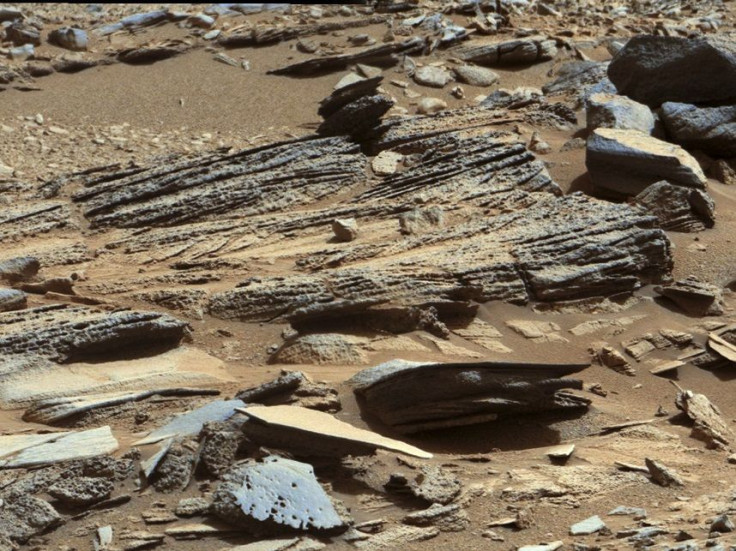

The second phase of the competition will be divided into two levels. The first level is called Structural Member Competition, and will focus on the processes and technologies needed to print and manufacture components from indigenous and/or recyclable materials. Rocky soil is an example of indigenous material, according to Web site Engadget.

Level 2 is called On-Site Habitat Competition, where participants will fabricate and build full-scale habitats using indigenous materials or indigenous , combined with recyclables.

The two levels will be open for registration on Sept 27, with each offering $1.1 million in cash prize. Winning entries and products will aid NASA to build and develop the expertise to send habitat-manufacturing machines to other planets, like Mars, to construct these living spaces.

3D printing has indeed taken off, with several space systems already using additive manufacturing to build space shuttle parts because of the lightweight properties it entails. Titanium is a main element in the technology, which means that demand for the metal will surge once 3D printing becomes more popular in this industry.

South America’s White Mountain Titanium (OTCQB: WMTM) is a developing mine in Chile that aims to produce 112 million tons of high-grade rutile, the ore which titanium comes from. Once White Mountain secures this kind of supply, companies, private sectors, and titanium distributors that practice 3D printing will have access to quality titanium that can be used for additive manufacturing.

To contact the writer, email: vittoriohernandez@yahoo.com